Cutting Optimization Pro 5.9.5.7(獲得最佳的切割佈局)

【文章內容】:

切割改善Cutting Optimization Pro 5.9.5.7是一個軟體應用程式(1D)和兩個(2D)立體作品,以獲得最佳的切割佈局。

該軟體還容許您定義和處理複雜的產品,如桌子,桌子,櫥櫃,衣櫃,書架…切割改善

可用於切割玻璃,木材,木材,金屬,傢俱,或任何其他的工業應用中所使用的材料製成的矩形片。

Cutting Optimization Pro 5.9.5.7(獲得最佳的切割佈局)特點:

在相同的切削專案的一維1D和二維2D改善 – 你可以使用的程式2D和1D改善的。

血滴子改善 – 從一個側面向其他的材料進行剪下。此功能是非常有用的玻璃,木材,thermopan,…

非鍘(嵌套)改善 – 切割機可以按照形狀的材料。在這種情況下,你需要有一個複雜的雷射或火焰刀片上機的基礎。

多級鍘 – 在一個階段的所有的切口垂直於切口的前級上。使用者可以指定階段,在第一階段的方向的切割的數量。

件的庫存量和需求 – 任意數量的數量幾乎沒有限制的作品,你要改善。

任何測量度量的模式,你介紹的資料是一個普遍的。你不必指定度量。只要選取一個度量在你的心中,只有使用該指標輸入的所有資料。

分數輸入。可以引入枚100.5 100 1/2。分數輸入更多訊息可以在這裡閱讀。

可調刀片厚度玻璃切割用金剛石切割鋸片厚度為0,但木材,金屬處理,你需要一個更大的厚度鋸帶。

可調改善層級-一指定多少佈局之前生成的輸出解決專案。如果你沒有太多的時間和你沒有一台好電腦,你可以設定改善層級,以一個較低的水平。此功能可以說明你運行你的程式在任何類型的電腦(從486到今天提供最好的處理器)。

最大切割長度的限制 – 您可以指定多長時間可以切。這是非常有用的,當您執行手動扦插。

可調有用的廢物 – 小於這個尺寸的所有廢物垃圾(不會被新增到版本庫)。

可調限易碎部件 – 無廢料將有低於此參數的大小,並沒有2個平行的削減將是比這更接近。這是為了避免過小的材料的斷裂。在玻璃工業中非常有用。

減少面板浪費和成本 – 通過使用人工智慧領功能變數的最新成果,你可以得到15%,減少浪費。

糧食方向控制 – 用於木材切割改善。一個參數,讓使用者指定,如果一塊可旋轉,或是它應保持固定。

自動邊角料處理 – 有用的廢物會自動加入的庫存材料。

垂直印刷的標籤和邊緣帶 – 這將改善和簡化您的佈局。

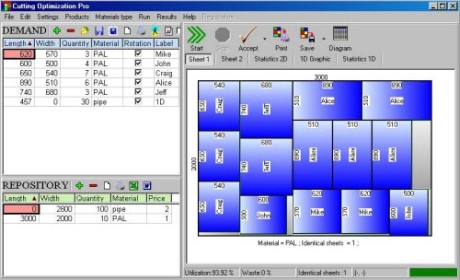

圖形顯示黑白或彩色圖像和文字模式下所獲得的結果 – 結果顯示圖像(黑白或彩色)或文字表。

自動儲存圖像 – 所有獲得的二維圖紙可以儲存為bmp圖像1點擊。程式自動追加一個數字圖像。

複製貼上從Excel。只要選取一些列從Excel,並將其貼上需求或庫存電網中。

分組相似的佈局 – 這將減少列印的紙張數量。為每個表的重複的數目將被顯示。

拉近一張。這是非常有用的,如果你有一個很長的卷,你可以想像它拉近。

– 在任何印表機上列印得到的佈局。

在同一頁上列印多個佈局 – 您可以列印在同一張紙上佈局1,2,4或6。

列印存儲庫和客戶的需求 – 你可以列印件,你要改善。

此次裁員中顯示的文字格式,以數控機床使用它們。

封邊條處理 – 的數量和不同的材料貼木紙的邊緣是由程式操縱。

計算/列印總切削長度。

顯示圖 – 一個表,其中包括每片裁片。

可以定義複雜的產品,如桌子,桌子,櫥櫃,衣櫃,書架…

的可能性來定義類型的材料(玻璃,木材,帶) – 為每個使用者有一個特殊的表,它可以引入更多的關於材料的訊息材料。

自動工具,用於計算基於該產品的外部體積的大小的碎片。

關聯統計現用的切入/佈局年底的改善過程中,你將有機會到:削減,削減的定義(起點和終點),數量廢物矩形,廢矩形(頂部的坐標數左上角和右下角的角落),利用件,利用片,用於安置面,數…

儲存/加載結果 – 所有結果都可以儲存在txt檔案和加載。

生成並列印不干膠標籤 –

加載XML資料,*。的DBT(特定的檔案),* .2 D(實際削減的2D檔案),*的。xls(Excel檔案),*。CSV(逗號分隔)* .1 D(真實剪下1D檔案)。

自動計算順序價 –

庫和需求可以排序 – 通過使用各種標準的長度,寬度,數量,類型,旋轉,標籤

Maximises生產力,節省了時間和金錢……

資料可以匯出成非常流行的格式的Word,Excel,HTML,CSV(逗號分隔),XML檔案。

所有的面板和表中的列是可調整大小的 – 您可以自訂工作區。新職位被自動存儲。

非常快的運行時間 – 在幾秒鐘內獲得解決專案。

改善引擎改善程式提供剪下二維X和剪下1D X元件。

介面多國語系:荷蘭語,英語,法語,德語,意大利語,葡萄牙語,羅馬尼亞語,西班牙語和瑞典語。

——————————————————————————–

【文章標題】: Cutting Optimization Pro 5.9.5.7(獲得最佳的切割佈局)

【文章作者】: 電子書製作教學密訓基地

【作者信箱】: ster168ster@gmail.com

【作者首頁】: http://por.tw/ebook

【電子書製作教學課程】: http://por.tw/ebook/new-ebook/index.php

【基地主機】: http://goto1688.com/ebook

【版權聲明】: (原創)電子書製作教學密訓基地,轉載必須保留完整標頭。刪除者依法追究!

——————————————————————————–

Cutting Optimization Pro 5.9.5.7

Cutting Optimization Pro is a software application used to obtain optimal cutting layouts for one (1D) and two (2D) dimensional pieces. The software also lets you to define and handle complex products, such as table, desk, cupboard, locker, book shelf … Cutting Optimization Pro can be used for cutting rectangular sheets made of glass, wood, woodworking, metal, furniture, or any other material used by industrial applications.

Features of Cutting Optimization pro …

1D and 2D optimization in the same cutting program – you may use the program for both 2D and 1D optimization.

Guillotine optimization – The cuts are performed from one side to the other of the material. This feature is very useful for glass, wood, thermopan, …

Non-guillotine (nested) optimization – The cutting machine can follow the shape of the material. In this case you need to have a complex machine based on laser or flame blade.

Multi-stage guillotine – all cuts in a stage are perpendicular to the cuts on the previous stage. The user may specify the number of stages and the direction of cuts for the first stage.

Any number of pieces in the INVENTORY and DEMAND – virtually no limit for the number of pieces that you want to optimize.

Any measurement metric- The way in which you introduce the data is a general one. You don't have to specify a metric. Just choose a metric in your mind and enter all data using that metric only.

Fractional input. Pieces can be introduced either as 100.5 or 100 1/2. More info about fractional input can be read here.

Adjustable cutting blade thickness- For glass cutting with diamond the cutting blade thickness is 0, but for wood, metal handling you need a saw with a greater thickness.

Adjustable optimization level- One may specify how many layouts to be generated before the solution is outputted. If you don't have too much time and you don't have a good computer you may set the Optimization Level to a low level. This feature helps you to run your program on any kind of computer (from 486 to the best processors available today).

Maximal cut length limit – You may specify how long a cut can be. This is useful when you perform the cuttings manually.

Adjustable useful waste – all wastes smaller than this size are garbage (will not be added to repository).

Adjustable limit for breakable parts – No waste will have a size lower than this parameter and no 2 parallel cuts will be closer than this. It is used in order to avoid the breaking of too small material. Useful in glass industry.

Reduces panel waste and costs – By using the latest achievements in the field of Artificial Intelligence you may obtain reduce the waste by 15%.

Grain direction control – useful for wood cutting optimisation. A parameter let the user to specify if the piece can be rotated or it should be kept fixed.

Automatic offcuts handling – the useful waste is automatically added to the Inventory of materials.

Vertical printing of the labels and edge bands – this will optimise and simplify your layout.

Graphical display black-white or colourful images and text mode of the obtained results – the results are displayed as images (black and white or colourful) or as text-tables.

Save images automatically – all the obtained 2D sheets can be saved as bmp images with 1 click. The programs automatically appends a number to an image.

Copy-paste from Excel. Just select some columns from Excel and paste them in Demand or Inventory grids.

Grouping similar layouts – this will reduce the number of printed sheets of paper. The number of repetitions for each sheet will be displayed.

Magnifying a sheet. This is useful if you have a long roll which you can visualize it by magnifying it.

Printing the obtained layouts – on any printer.

Printing multiple layouts on the same page – You may print 1, 2, 4 or 6 layouts on the same sheet of paper.

Printing the REPOSITORY and the DEMAND of the customer – you may print the pieces that you want to optimize.

The cuts are shown in text format in order to use them with a CNC machine.

Edge banding handling – the quantity and the type of material attached to the edges of the wood sheets is manipulated by the program.

Computes / Prints the total cutting length.

Displays diagrams – a table which contain the pieces cut for each sheet.

Possibility to define complex products such as table, desk, cupboard, locker, book shelf …

Possibility to define types of materials (glass, wood, band) – for each material the user has a special table where it can introduce more information about the material.

Automatic tool for computing the size of the pieces based on the external sizes of the product.

Statistics related to the current cut / layout- At the end of the optimisation process you will have access to the: number of cuts, cuts definition (starting and ending point), number of waste rectangles, the waste rectangles (the coordinates of the top-left and bottom-right corners), number of utilized pieces, the placement of the utilized pieces, used surface, …

Saves/loads results – All results can saved in txt files and loaded later.

Generates and prints adhesive labels –

Load data from xml, *.dbt (specific files), *.2d (Real Cut 2D files), *.xls (Excel files), *.csv (comma separated) and *.1d (Real Cut 1D files).

Automatically computing of the order price –

The REPOSITORY and the DEMAND can be sorted – by using various criteria: Length, Width, Quantity, Type, Rotation, Labels

Maximises productivity, saves time and money ….

Data can be exported into very popular formats: Word, Excel, HTML, CSV (comma separated) and XML files.

All panels and table's columns are resizable – You may customize the workspace. The new positions are automatically stored.

Very fast running time – Solutions are obtained within seconds.

Optimization engines provided by Optimal Programs Cut 2D X and Cut 1D X components.

Interface in multiple languages: Dutch, English, French, German, Italian, Portuguese, Romanian, Spanish and Swedish.

Cutting Optimization Pro 5.9.5.7(獲得最佳的切割佈局) | Homepage: cutting-optimization.optimalprograms.com

Cutting Optimization Pro 5.9.5.7(獲得最佳的切割佈局) | Size: 3.1 MB

——————————————————————————–

【電子書製作教學】你在摸索如何製作電子書製作及加密防盜版嗎?有【技術顧問服務】可諮詢嗎?

當問題無法解決你要發很多時間處理(或許永遠找出答案)那就是自己摸索電子書製作痛苦的開始!

購買【電子書製作教學】函授課程錄影DVD課程,就可獲得【電子書製作】技術【顧問諮詢服務】!